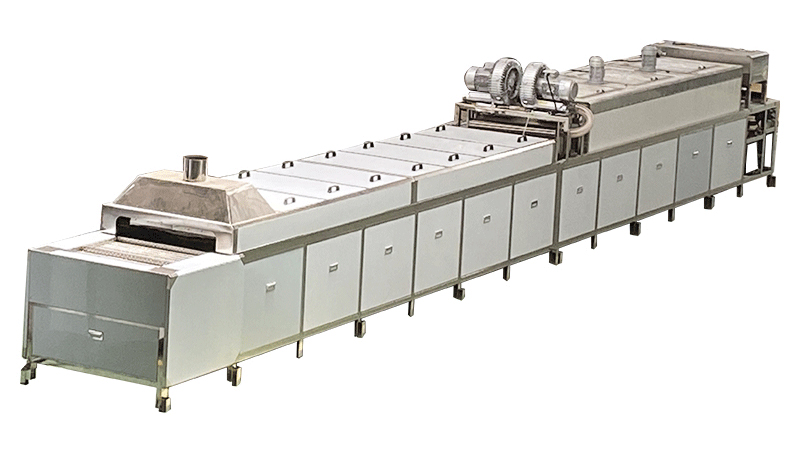

The cleaning process of the spray cleaning equipment is automatically controlled by the PLC programming, and the equipment is device, a washing room, a solution box, a circulating filtration system, heating system, a water cutting system, an oil removal system, and a drying system. Its working principle is to make the workpiece achieve the purpose of cleaning, oil removal, and water cutting through the surface of high -pressure water spray shock workpiece and combining the cleaning agent.

The work process is to place the workpiece directly on the device's transmission network chain; turn on the equipment, and choose the work method to run automatically until the feeding. This is to complete a work cycle to enter the next work cycle and continue.

This machine uses automatic transportation cleaning, stable operation, the subsequent subsequent process can be adjusted, the cleaning effect is good, and the production efficiency is high. It has the characteristics of reasonable structural, stable performance, and long service life.

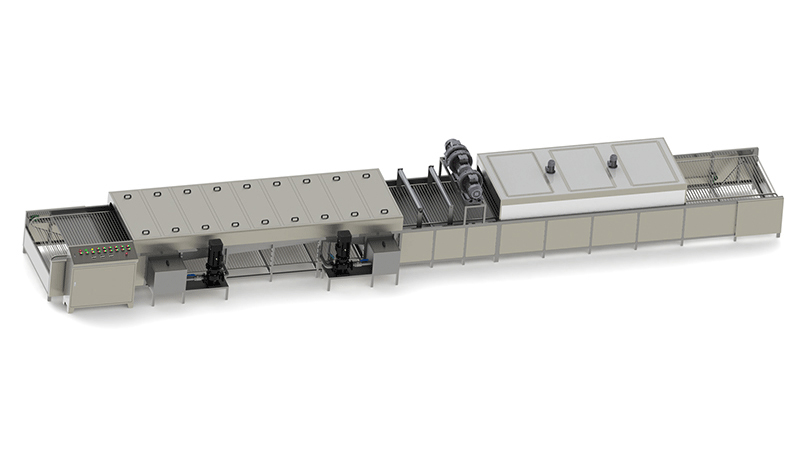

Fully automatic passing ultrasonic cleaning line industrial ultrasonic cleaning machine quality guarantee

The equipment is mainly composed of automatic transport chain, spraying room, spraying system, oil removal device, filtering circulation system, water cutting system, drying system and electrical control system. For details, please refer to the attachment structure.

1. Automatic conveyor chain: transmit stainless steel and chain transmission, and continuously advance through the type to ensure that the cleaning basket is smooth and accurately running.

2. Spraying system: Spray and cleaning a total of two sets, one uses a potion spray cleaning, the second path uses spray rinsing, the third road uses spray drift, spray rinsing in the fourth, and the fifth road uses spray rust prevention, inner inner, inner inner Sprinkle in a cavity, a stainless steel nozzle on the nozzle, and an error arrangement between the upper and lower spray gymnasis to make the cleaning workpiece fully ensure that there is no spray blind area when the workpiece is cleaned in the cleaning area, and the cleanliness of the workpiece was cleaned.

3. Oil removal device: Due to the large processing volume of the previous cleaning station, the oil content in the cleaning solution is more. In order to prevent the oil content in the drainage, the oil removal system is provided.

4. Filter circulation system: Cleaver in the circulating filter slot to improve the cleaning effect. Use a bag filter.

5. Water cutting system: Discharge into the total drainage pipe in the water cavity, there is an isolation section in the feed and external discharge to prevent the water fog from mutualizing. Clean up.

6. The gas pumping system: The spray and wind cut section are open on the side with a pump connection to the supervisor.

7. Electrical control system: Independent control cabinet, interior PLC programming controller, inverter, contactor and other main order electrical control components, select imported brand -name components assembly, stable performance, reliable life, long service life, control lines see electrical control electrical control picture.

Post time: Sep-05-2023